Private Label

fillers | cosmeceuticals | devices

who we are

We stand alongside our clients to study personalized projects and develop different lines of products in the medical and aesthetic field with dermal fillers, devices and cosmeceuticals.

Established in 2012 as a scientifically-based medical aesthetics company, Matex Lab Group has evolved into a vibrant, high-growth multinational corporation with considerable experience in the production of quality injectables, topicals and cosmeceuticals, electro-medical devices, for the medical and aesthetic field.

A uniquely innovative aesthetic company with:

- A STRONG VISION of empowering people to take control of their ageing process from the inside out;

- AN UNDENIABLE SCIENTIFIC DNA with exceptional and highly differentiated products across the Fillers, Devices, Cosmeceuticals verticals;

- A SOLID and STATEof the ART PRODUCTION STRUCTURE,with 6 production sites in Europe

Services

Innovation

Innovation embraces not only our products but also our processes and infrastructures with an engineering approach.

Thanks to computerized production processes, which are monitored by advanced management programs, products are mapped and managed individually.

Production

The group owns a real state of the art production equipment.

Starting from the first stages of each product development, our supply chain is contributing effectively and efficiently in achieving the desired outcome.

Scientific board

Our Scientific Board consults and involves professors of international prestige in the design of the R&D strategy.

A strength asset of the company is represented by a network of medical specialists.

The group is constantly strategically involved in R&D development and in the structuring of training and awareness raising initiatives.

R&D

Successfully responding to the market’s needs and anticipating market requirements is crucial for us. For this reason, we have a dedicated infrastructure with an R&D laboratory which helps us to deliver the best service thanks to our relationships with key opinion leaders (KOL) and by a close partnership with the client.

Quality

Quality is central to everything we do, both in internal processes and in finished products.

We work in compliance with the highest international standards and we guarantee processes and infrastructures owning superior certifications.

The group brings forward constant internal controls and external laboratory tests together with managing a perfect traceability and post-sales support.

Regulatory

The Regulatory department is formed by a specialized team with 15+ years of experience in medical devices and cosmeceuticals.

This section has dedicated resources with scientific and legal background, language skills and international exposure.

The team offers a unique ability to design the regulatory strategy and direct the practical steps while addressing the right people. We combine rigor with the perfect dose of pragmatism.

Logistic and distribution

The group disposes of organized warehouses where teams with exceptional expertise in international shipping management and customer dynamics respond to each customer’s requirement.

Our staff is dedicated to interfacing with customers operating under their own brand (private label) on international markets.

Sustainability

Together with constant research and innovation, the group is continuously adopting measures to reduce its emissions internally and during the export activities.

In particular, our production facilities are equipped with solar panels

to increase the use of natural energy and reduce any additional consumption.

Furthermore, the group has removed every form of plastic in the packaging of the products from the Fillers to the Cosmeceuticals to guarantee sustainable products from the inside out.

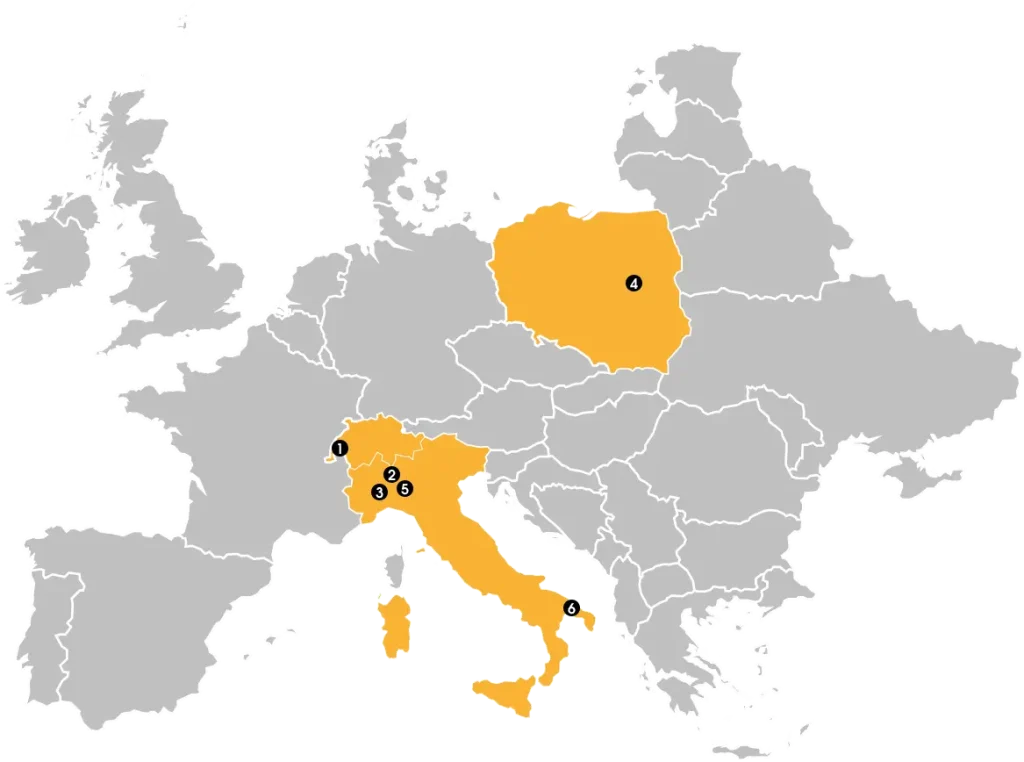

Our facilities location

Geneve

Switzerland

Matexlab’s Headquarters in Geneva serves as the central hub for all its business operations, providing a strategic location for managing global activities.

Pavia

Italy (Milan)

Matexlab’s R&D facility in Pavia is a fully certified laboratory dedicated to continuous analysis and research, ensuring the highest standards of safety and quality for its products. The lab conducts rigorous studies to innovate and enhance product performance while adhering to stringent industry regulations.

Lentate sul Seveso

Italy (Milan)

Our cosmeceuticals production facility, spanning 1800 sqm near Milan, integrates internal R&D and Regulatory departments to ensure cutting-edge product development. Fully certified, it adheres to the highest industry standards for quality, safety, and compliance throughout the production process.

Raszyn

Poland

Our electro-medical device production facility in Poland spans 5,500 sqm, with an additional 4,000 sqm dedicated to warehouse space, enabling efficient manufacturing and distribution. Equipped with internal R&D and Regulatory departments, it delivers the latest innovative technologies while ensuring the highest standards of safety and compliance.

Belgioioso

Italy (Milan)

Our fillers production facility near Milan covers 1,800 sqm and is equipped with advanced, innovative technologies to ensure top-tier product quality. Fully certified, it also houses R&D and Regulatory departments, ensuring continuous development and compliance with the highest industry standards.

Brindisi

Italy

Our fillers production facility in Brindisi spans 1,200 sqm, with continuous analysis to ensure the highest quality, safety, and performance of BDDE hydrogels. Fully certified, with in-house R&D and Regulatory departments, it is committed to offering the best products and services, ensuring reliability and excellence in every aspect of production.

One company,

three solutions

Fillers

Our unique injectables are available with a full customization possible – from the cross-linking technology to the HA concentrations, the packaging preferences and the final product registrations ready for the end consumer.

Product range attributes

- MDR-certified range of SKUs for full-face treatment

- Several HA products available

- Uniquely rheological properties tuned for each customizable formulation

- Presence of amino-acids (glycine and l-proline) to tune the rheological properties (viscoelastic properties) of the HA hydrogel and the swelling resistance

- Cross-linked or non cross-linked HA available

- Full customization possible

- Proven technology with millions of syringes sold, no pathologic inflammatory reaction and severe adverse events have been reported up to now

3 N° factories

4.500 Total sqm

2.000 Production sqm

Cosmeceuticals

Our unique cosmeceuticals are the outcome of broad expertise, advanced delivery technologies and hundreds of experiments with the aim of providing you the highest quality and safety.

Additionally, we offer the possibility of fully customize your products: it’s formulation, texture, perfume and packaging.

Product range attributes

- Proprietary technologies with own R&D department and Quality Control department

- Presence of Sonicated Hyaluronic Acid with high concentration of active ingredients

- High stability with shelf life ranging from 3-5 years

- Full customization possible (formulation, texture, parfum, packaging)

- Possibility to produce sterile product, 100% active ingredients (no preservatives), pharmaceutical grade

2 N° factories

1.800 Total sqm

1.500 Production sqm

Devices

Our 5.500 sqm facility, thanks to the latest manufacturing technologies, is offering the most advanced machines to support your business and respond to the latest market’s demands.

Technologies

Our electro-medical devices production specializes in entirely customized technologies, providing cutting-edge solutions across various fields.

As developed technologies, we offer progress and innovation in:

- Lasers

- Electrosurgery

- Infrared

- Water peeling

- Radiofrequency

- Sanitization

Ensuring advanced performance and reliability.

1 N° factories

5.500 Total sqm

1.100 Production sqm